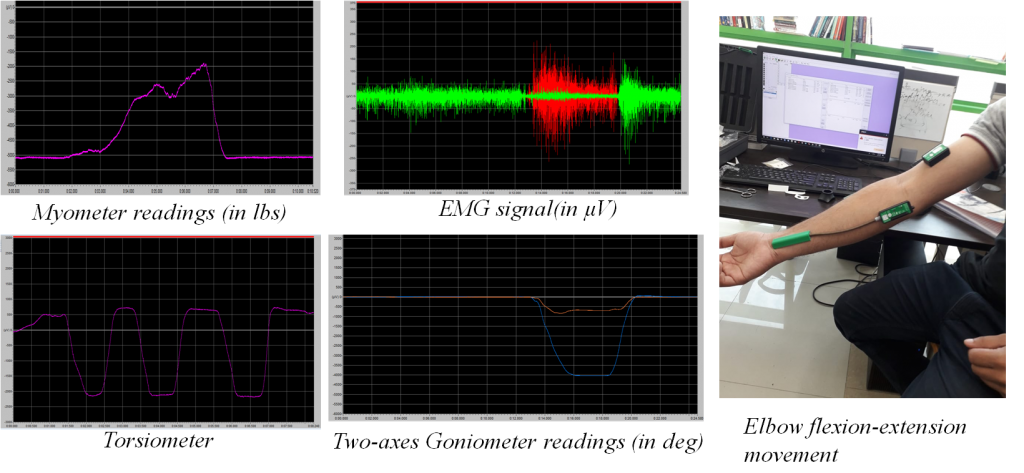

Experimental set-up for patient assessment and torque computation

lo trovi qui

This experimental set-up is designed to map the characteristics of human motion with the help of the characteristic of some sensors such as Myometer, Electromyography (EMG) sensor, Torsiometer and two-axes Goniometer. This set-up is directly linked to human-limb and help to compute the muscle strength and joint torque of human. The experimental set-up can generate the data to make the exoskeleton be simple, humanlike, and adaptable to any user.

The 4-DoF robotic arm of Kinova named as Mico-2, designed especially to do assistive tasks for handicapped persons. This is a lightweight arm which can be installed easily and quickly on different locations in no time. Due to its lightweight and payload capacity of up to 5 Kgs. Arm with moving base is the most common application of this Mico-2.

überprüfen sie diesen link hier

Humanoid Robot by NAO has total 24 degrees of freedom and has plenty of sensors viz. tactile sensors, Sonar sensors, Cameras, microphone etc. This humanoid robot can do many basic functions like Sit-stand and vice versa, walk, dance, etc.

Wall climbing robot by Winbot. It has the main application as whiteboard cleaning. It uses vacuum pressure to stick to the wall and has two wheels for its forward and backward motion.